Jet engine technology serves as a cornerstone of modern aviation, enabling the rapid transportation of goods and individuals across vast distances. The efficiency and reliability of jet engines have transformed air travel, making it accessible to millions globally. These engines not only power commercial airliners but also military aircraft, providing nations with strategic advantages in defence.

Moreover, the advancement of jet engine technology is pivotal for environmental sustainability. Modern engines are being designed to be more fuel-efficient, emitting lower levels of carbon dioxide and other pollutants. This shift is crucial as the aviation sector faces increasing scrutiny over its environmental impact. Thus, mastering jet engine technology is not just about enhancing aviation capabilities but also about aligning with global sustainability goals.

India, with its burgeoning aerospace ambitions, recognizes the significance of developing indigenous jet engine technology. The country aims to reduce dependency on foreign manufacturers and bolster its defence capabilities. However, the journey toward achieving this goal is fraught with challenges that require a thorough understanding of the underlying complexities.

India’s Aerospace Ambitions: A Brief Overview

India has long nurtured aspirations of becoming a major player in the global aerospace sector. The establishment of organizations like the Indian Space Research Organisation (ISRO) and Hindustan Aeronautics Limited (HAL) underscores the country’s commitment to advancing its aerospace capabilities. Despite notable achievements in satellite launches and aircraft manufacturing, the development of jet engines remains a key gap in India’s aerospace ecosystem.

In recent years, the government has unveiled various initiatives, such as the “Make in India” campaign, aimed at fostering domestic manufacturing and innovation. This initiative seeks to attract investments and encourage collaboration between public and private sectors, which could potentially catalyze advancements in aerospace technology. However, the focus has predominantly been on airframe and systems integration, with jet engine development lagging behind.

Furthermore, India’s strategic location and growing air travel demand present an opportunity for the nation to develop its indigenous jet engine technology. By focusing on this critical area, India could not only bolster its defence capabilities but also position itself as a competitive player in the global aerospace market. However, realizing this ambition requires overcoming significant hurdles that have persisted for decades.

The Complex Science Behind Jet Engine Manufacturing

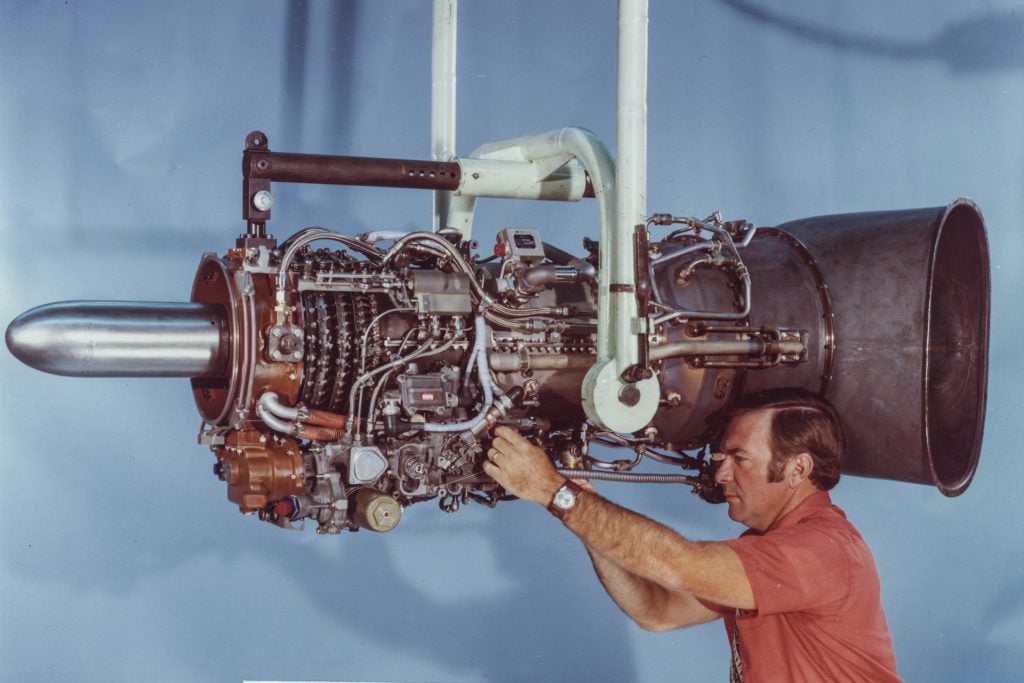

Jet engine manufacturing is a highly complex and specialized field that integrates advanced engineering disciplines. The process involves the design, testing, and production of various components, including compressors, combustors, and turbines. Each of these parts must work in unison under extreme conditions, necessitating a deep understanding of thermodynamics, fluid mechanics, and materials science.

The precision required in manufacturing jet engines cannot be overstated. Even minute discrepancies in design or production can result in catastrophic failures. Consequently, manufacturers must adhere to stringent quality control standards and undergo rigorous testing protocols. This not only demands advanced technical expertise but also significant financial investment in research and development.

Moreover, the rapid pace of technological advancement in jet engine design poses an additional challenge. The industry is constantly evolving, with manufacturers striving to develop engines that are lighter, more fuel-efficient, and capable of operating at higher altitudes and speeds. Keeping up with these advancements requires continuous innovation and investment, which India currently lacks in its jet engine development programs.

Current State of India’s Jet Engine Development Programs

India’s current state of jet engine development is characterized by ambitious projects and a recognition of the need for self-reliance. Organizations such as HAL are working on projects like the Kaveri engine, intended for the Tejas fighter aircraft. However, despite years of effort, the Kaveri engine has faced numerous challenges, including performance issues and delays in testing.

The government has acknowledged the importance of indigenous jet engine technology and has increased funding for research and development. Yet, progress remains slow. The complexities of jet engine design and the high costs associated with research have led to significant setbacks in timelines and deliverables. Consequently, India continues to rely on foreign suppliers for critical components and technologies.

In contrast, countries like China and Brazil have made substantial strides in developing their jet engine capabilities, highlighting the urgency for India to accelerate its efforts. The gap in technology and expertise is evident, and without a focused approach, India’s aspirations of becoming a leader in aerospace could remain unfulfilled.

Key Challenges Hindering India’s Jet Engine Production

The development of a robust jet engine manufacturing capability in India is hindered by several key challenges. First and foremost is the technological gap. India lacks the critical expertise and advanced materials required for designing and manufacturing high-performance jet engines. This gap is compounded by limited access to cutting-edge research and development facilities.

Another significant challenge is the financial investment required for jet engine development. The costs associated with research, prototyping, and testing are substantial. Although the government has made efforts to increase funding, the scale of investment needed to compete with established aerospace nations is still lacking. Private sector involvement and foreign partnerships could play a crucial role in bridging this financial gap.

Key Challenges in Developing Jet Engines

- Technological Complexity:

- Jet engines are intricate machines composed of over 30,000 parts, requiring advanced metallurgy and precision engineering. The technology involved is closely guarded by leading nations, making it difficult for India to gain access to the necessary know-how and materials.

- Historical Setbacks:

- The Kaveri jet engine program, initiated in 1986, was intended to power the Tejas fighter jet but has faced numerous delays and failures due to inadequate funding, lack of infrastructure, and insufficient testing facilities. This project remains emblematic of India’s broader struggles in jet engine development.

- Infrastructure Limitations:

- India lacks the high-end manufacturing capabilities and testing facilities required for jet engine production. Critical components like single crystal blades and integrated blisk designs remain outside India’s current technological reach. Testing often has to be conducted abroad due to insufficient local resources.

- Political and Economic Factors:

- Geopolitical tensions and sanctions have hindered technology transfers from other countries, particularly after India’s nuclear tests in 1998. This has limited collaboration opportunities with nations that possess advanced aerospace technologies.

- Research and Development Gaps:

- There is a shortage of trained personnel and consistent R&D efforts in cutting-edge technologies related to jet engines. Projects often arise only when there is a specific requirement from the military, leading to sporadic development rather than a sustained focus on innovation.

- Dependence on Foreign Engines:

- Currently, India relies on foreign engines like the GE F404 and F414 for its fighter jets, which restricts design flexibility and performance capabilities of its aircraft programs. This reliance continues to stymie efforts toward achieving self-sufficiency.

Furthermore, bureaucratic hurdles and regulatory constraints can impede progress. The aerospace sector in India is subject to various regulations that can slow down the development process. Streamlining these regulations and fostering a more conducive environment for innovation is essential for accelerating India’s jet engine manufacturing capabilities.

Technological Gaps: Materials, Design, and Testing

One of the most significant technological gaps India faces in jet engine manufacturing is in the area of materials. Modern jet engines require advanced materials that can withstand extreme temperatures and pressures. Superalloys, composites, and ceramic matrix materials are commonly used in high-performance engines, but India currently lacks the capabilities to produce these materials in sufficient quantities.

In addition to materials, the design process of jet engines is highly sophisticated. Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) tools are essential for simulating engine performance and ensuring optimal design. India needs to enhance its capabilities in these areas to improve the design efficiency of its indigenous engines. Investment in research institutions and collaboration with international experts could help address these deficiencies.

Testing is another critical aspect of jet engine development. Engines must undergo rigorous testing to validate their performance and safety. India currently lacks comprehensive testing facilities that can simulate the extreme conditions experienced by jet engines. Establishing state-of-the-art testing facilities is vital for accelerating the development process and ensuring that indigenous engines meet international standards.

Economic Factors: Investment and Research Funding

Economic factors play a crucial role in the development of jet engine technology in India. The financial commitment required for research and development is immense, and without sustained investment, progress will be limited. While the Indian government has increased funding for aerospace initiatives, the scale of investment still falls short of what is needed to compete with established aerospace nations.

The involvement of the private sector is essential to enhance investment in aerospace research. Collaborative projects between public and private entities can facilitate the sharing of resources and expertise, ultimately accelerating the development process. Encouraging foreign direct investment and establishing partnerships with international aerospace companies could also provide the necessary funding and technological know-how.

Moreover, the potential economic impact of successful jet engine production cannot be overstated. Developing indigenous jet engines would not only reduce reliance on foreign suppliers but also create a self-sustaining aerospace ecosystem. This would lead to job creation, increased exports, and a stronger position in the global aerospace market. The long-term economic benefits justify the need for increased investment in this critical sector.

Geopolitical Constraints: Technology Transfer and Sanctions

Geopolitical factors significantly impact India’s ability to develop jet engine technology. The nation has often faced challenges in obtaining critical technologies due to international sanctions and regulatory constraints. These limitations hinder technology transfer, which is essential for developing advanced aerospace capabilities.

In addition, India’s relationships with key aerospace nations can influence access to technology and resources. For instance, collaboration with countries like the United States, Russia, and France has historically been fraught with challenges. While agreements have been made, the implementation of technology transfer often faces bureaucratic delays and regulatory hurdles, further complicating India’s efforts.

To address these geopolitical constraints, India must foster stronger international partnerships and engage in diplomatic efforts to ensure the smooth transfer of technology. Building trust with key players in the aerospace sector will be crucial for overcoming these challenges and establishing a viable jet engine manufacturing capability.

Comparison with Other Emerging Aerospace Nations

When comparing India with other emerging aerospace nations, significant disparities in jet engine development capabilities become evident. Countries like China and Brazil have made considerable investments in indigenous jet engine technology, resulting in the successful development of homegrown engines. These nations have leveraged government support, private sector involvement, and international collaborations to accelerate their progress.

China, for instance, has established a comprehensive aerospace ecosystem that includes research institutions, manufacturing facilities, and testing centers. The Chinese government has prioritized aerospace development, resulting in significant advancements in jet engine technology. In contrast, India’s fragmented approach has led to slower progress in this critical area.

Brazil’s Embraer has also made strides in jet engine technology, focusing on partnerships with international firms to enhance its capabilities. By learning from the successes and strategies of these nations, India can identify areas for improvement and adopt best practices to expedite its own jet engine development efforts.

Future Prospects: India’s Roadmap to Jet Engine Manufacturing

The future prospects for India’s jet engine manufacturing capabilities hinge on a clear and strategic roadmap. To achieve self-reliance in this critical technology, India must prioritize investment in research and development. Establishing dedicated research institutions focused on aerospace engineering and materials science can foster innovation and enhance domestic capabilities.

Furthermore, fostering collaboration between public and private sectors will be essential. Encouraging partnerships with international aerospace companies can facilitate technology transfer and knowledge sharing. Joint ventures and collaborations can help India leverage existing expertise while developing its indigenous capabilities.

Additionally, the government must streamline regulations to create a more conducive environment for innovation. Simplifying the bureaucratic processes associated with aerospace projects will enable faster decision-making and implementation. With a strategic approach, India can pave the way for successful jet engine production and position itself as a competitive player in the global aerospace landscape.

Collaborative Efforts and International Partnerships

Collaborative efforts and international partnerships are critical for advancing India’s jet engine manufacturing capabilities. Engaging with established aerospace nations can provide access to cutting-edge technologies, best practices, and expertise. These collaborations can take various forms, including joint ventures, research collaborations, and technology transfer agreements.

India’s participation in international aerospace forums and initiatives can also facilitate knowledge sharing and networking opportunities. By engaging with global leaders in the aerospace sector, India can gain insights into emerging trends and technologies, enhancing its own capabilities in jet engine development.

Moreover, fostering a culture of innovation and collaboration within the domestic aerospace ecosystem is essential. Encouraging startups and research institutions to engage with established players can create a vibrant ecosystem that fosters technological advancements. This collaborative approach can drive India’s progress toward achieving self-reliance in jet engine manufacturing.

The Role of Education and Skilled Workforce Development

A skilled workforce is fundamental to the success of India’s jet engine manufacturing aspirations. As the aerospace sector grows, the demand for highly specialized engineers, researchers, and technicians will increase. Therefore, investing in education and workforce development is paramount to building a strong talent pool.

India must enhance its educational programs in aerospace engineering and related fields. Collaborating with leading universities and institutions worldwide can help develop curricula that align with industry needs. Additionally, promoting internships and practical training programs can provide students with hands-on experience, preparing them for careers in aerospace.

Furthermore, continuous professional development opportunities for existing professionals in the field are essential. Offering specialized training programs and workshops can help individuals stay updated on the latest advancements in jet engine technology. By prioritizing education and workforce development, India can cultivate a skilled labor force capable of driving innovation and progress in aerospace.

Government Initiatives to Boost Aerospace Capabilities

The Indian government has recognized the need to boost the country’s aerospace capabilities and has launched several initiatives to support this goal. Programs like “Make in India” and “Atmanirbhar Bharat” emphasize self-reliance and domestic manufacturing. These initiatives aim to create a conducive environment for the growth of the aerospace sector, including jet engine manufacturing.

In addition to policy initiatives, the government has increased funding for research and development in aerospace technology. Establishing aerospace parks and research centers across the country will encourage collaboration between industry and academia, fostering innovation and technological advancements.

Moreover, the government is focusing on simplifying regulatory frameworks to expedite project approvals and reduce bureaucratic hurdles. By creating a more favorable business environment, India can attract investments and encourage private sector participation, ultimately enhancing its aerospace capabilities.

Potential Impact of Successful Jet Engine Production on India’s Economy

The successful production of jet engines in India could have a transformative impact on the country’s economy. Reducing dependency on foreign suppliers would bolster national security and enhance the domestic aerospace industry’s competitiveness. Additionally, the establishment of a robust jet engine manufacturing sector would create job opportunities across various skill levels, contributing to economic growth.

Moreover, the development of indigenous jet engines could pave the way for increased exports. As global demand for aerospace products continues to rise, India could position itself as a significant player in the international market. This would not only boost the economy but also enhance India’s standing on the global stage.

Furthermore, successful jet engine production could stimulate innovation in related industries, such as materials science, manufacturing, and engineering. The ripple effect of advancements in jet engine technology would contribute to the overall growth of the aerospace ecosystem, fostering a culture of innovation and collaboration.

Conclusion: Overcoming Hurdles for a Self-Reliant Aerospace Sector

In conclusion, while India has made significant strides in its aerospace ambitions, the journey toward self-reliant jet engine manufacturing is fraught with challenges. Addressing technological gaps, increasing financial investment, and fostering international collaborations are crucial steps toward achieving this goal.

The role of education and skilled workforce development cannot be overlooked, as a well-trained talent pool is essential for driving innovation. Government initiatives aimed at boosting aerospace capabilities must continue to evolve to create a favorable environment for growth.

With a concerted effort from all stakeholders—government, industry, academia, and the workforce—India can overcome the hurdles it faces. By focusing on the development of indigenous jet engine technology, India can secure its position in the global aerospace market and pave the way for a prosperous future.

As India embarks on this challenging yet promising journey, it is imperative that all stakeholders remain committed to fostering innovation, collaboration, and investment in aerospace. Together, they can turn aspirations into reality and establish a self-reliant aerospace sector that contributes significantly to the nation’s economy.